The Edgewood Chemical Biological Laboratory (ECBC) recently acquired a new machine that improves the efficiency and safety in processing orders of dilute chemical agents used for research and testing.

Brandon Bruey, chemist at ECBC’s Chemical Transfer Facility (CTF), said the dilute samples contain a high-purity sample of chemical agent dissolved in solvent that has been analyzed and certified so that other research labs know what concentration with which they are working.

He added that most customers utilize the dilute agent solutions as standards to ensure they can identify and quantify chemical agent material on analytical instrumentation.

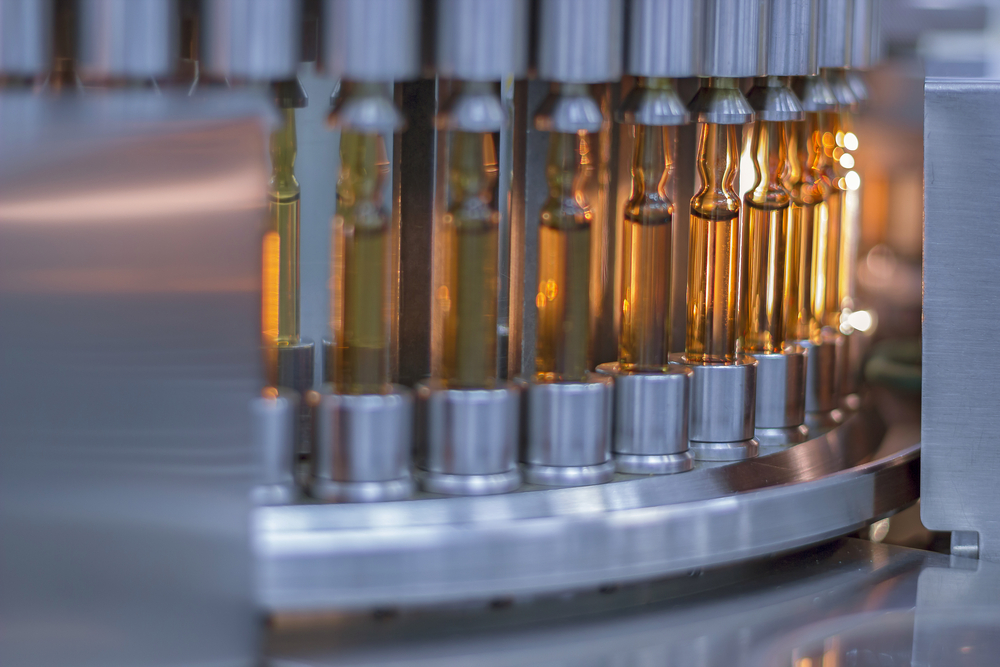

After dilute solutions are certified by ECBC, they must be injected into open-ended glass ampules, which are heat-sealed closed for safe transport and handling. Until recently, each ampule had to be sealed using a hand torch and glass rod, which, according to Bruey, was a time-consuming and labor intensive process.

ECBC’s CTF will now use a new bench-scale ampule sealer that automatically closes each vial. First, the ampules are loaded onto a circular carousel, which individually pass in front of a fixed torch. The machine then evenly melts glass seals without the issues seen with hand-sealing, such as glass bubbles or leaky vials.

“This gives every one of our vials a uniform seal and speeds up the process immensely,” Bruey said.

According to ECBC, the new machine provides consistent heating with a gas mixture of oxygen and propane that is control to ensure the best flame temperature.

“Once the flame temperature and weld times are set, the ampule sealer will produce a more uniform seal for all ampules,” Bruey said. “It takes human error out of the equation.”

While the machine does ensure a safer process, it still takes a team of four to complete a production run — one to fill ampules, one to operate the ampule sealer, one to ensure vials are fully sealed, and one to correctly label each ampule.