Researchers at the Lawrence Livermore National Laboratory (LLNL) have developed smart, breathable fabric designed to protect against biological and chemical warfare agents.

The material could be used by healthcare workers and first responders in clinical and medical settings as well as military personnel exposed to chemical and biological threats.

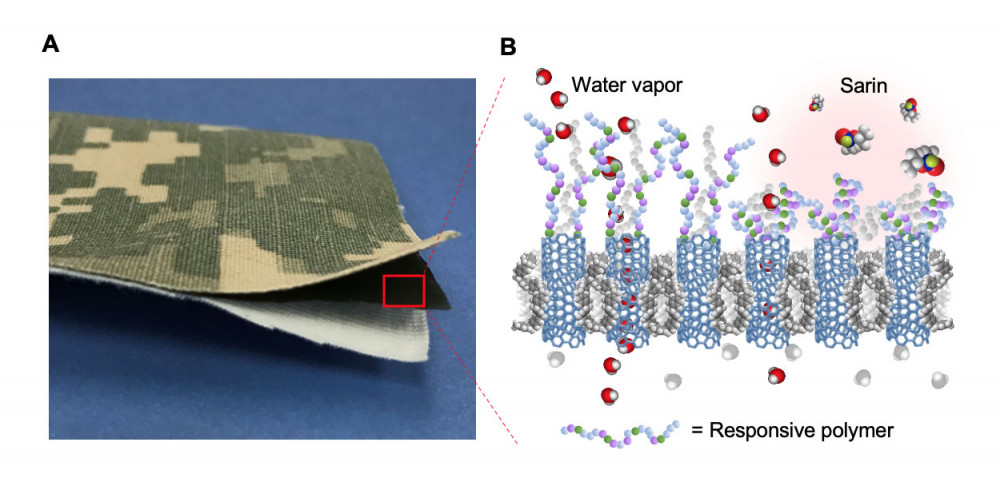

“We demonstrated a smart material that is both breathable and protective by successfully combining two key elements: a base membrane layer comprising trillions of aligned carbon nanotube pores and a threat-responsive polymer layer grafted onto the membrane surface,” Francesco Fornasiero, a scientist at LLNL who led the research team, said.

These carbon nanotubes can easily transport water molecules through their interiors while also blocking all biological threats, which do not fit through the tiny pores.

Chemical threats are smaller and can fit through the nanotube pores. So, to add protection against chemical hazards, a layer of polymer chains is grown on the material surface, which collapses when in contact with the chemical, thus blocking the pores.

“This dynamic layer allows the material to be ‘smart’ in that it provides protection only when and where it is needed,” Timothy Swager, a collaborator at the Massachusetts Institute of Technology who developed the responsive polymer, said. “These polymers were designed to transition from an extended to a collapsed state in contact with organophosphate threats, such as sarin. “We confirmed that both simulants and live agents trigger the desired volume change.”

The breathability and smart protection properties of this material should provide significantly improved thermal comfort for the user, whether he or she is in a hospital or on a battlefield.

“The safety of warfighters, medical personnel, and first responders during prolonged operations in hazardous environments relies on personal protective equipment that not only protects but also can breathe,” Kendra McCoy, the DTRA program manager overseeing the project, said. “DTRA Second Skin program is designed to address this need by supporting the development of new materials that adapt autonomously to the environment and maximize both comfort and protection for many hours.”