Air Force officials have launched a new initiative designed to keep the branch’s supply chain system independent of the civilian medical market amid the COVID-19 pandemic.

The Air Force Rapid Agile Manufacturing Platform (AFRAMP) seeks to leverage the full capacity of the nation’s manufacturing base by recognizing two challenges: relying on single-purpose investments to one company, one factory line, and one supply chain – limiting the flexibility of getting supplies where they were needed most and the fact a significant percentage of manufacturing is still occurring overseas – decreasing the nation’s positive control over the supply chain.

“This pandemic has placed a massive strain on the medical industry due to a significant increase in demand for supplies like masks and ventilators,” Maj. Chris Wood, DAF ACT AFRAMP lead, said. “Many U.S.-based suppliers are doing what they can to increase their capacity, but there’s more unmet demand out there. We decided to turn to nontraditional suppliers — like car manufacturers and 3D-printing factories — to explore how they can contribute in making different products for the Department of the Air Force.”

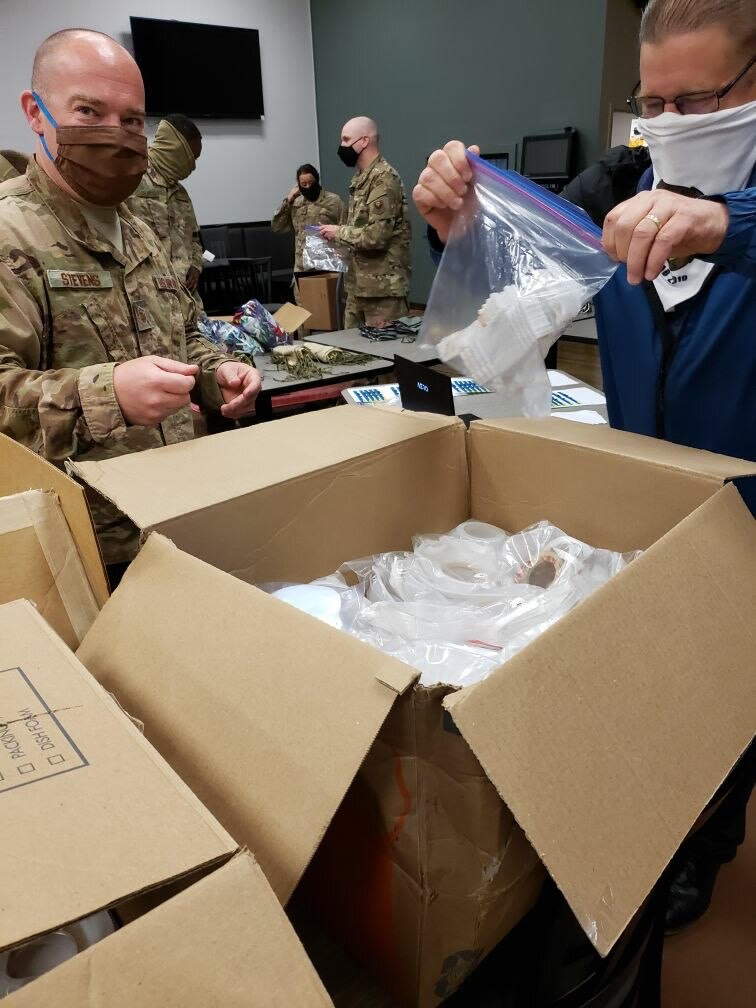

The RAMP team has delivered approximately 13,000 items to service members in career fields like security forces, aircraft maintenance, and training at locations like Joint Base Andrews, Md., and Schriever Air Force Base, Colo.

“Bringing the 11th Security Forces Group into this pilot program reinforces readiness and preparedness to respond and execute our no-fail mission at Joint Base Andrews,” Lt. Col. David Herndon, 11th Security Support Squadron commander, said. “Experimenting and exploring faster ways to deliver capabilities to our first responders has been exciting for our supply professionals.”